HOW TO CHOOSE THE RIGHT FREEZER FOR YOUR PRODUCTION LINE

12 Tue, 2019

To choose the correct freezer for your application and need is an important task as negligence can result in yearly costs that will exceed the total investment. Often overlooked are difficult to measure values like dehydration and the value of an enhanced appearance of the finished product. It is more and more common that the producers are paid by thawed weight and thus drip loss by thawing means a lot in the economical balance.

Your new freezer will serve you many years to come and a profound evaluation of your need and that of the market can offer you a good pay off. This paper is not a complete study but is intended to help you avoid the most obvious traps. We will be glad to add in information and support you in your selection.

The market

From what has been seen as a cheap alternative, freezing today has found new channels to reach customers prepared to pay for high quality frozen products. New driving forces are customer oriented outlets that only supply top quality frozen food – the target group is the wealthy middle class in all countries, which is prepared to buy exotic products that normally do not existing in their own country. Ready to eat products set new high standards on Food Safety and the market is there, and it is growing fast. Other well-known factors are convenience and less people households that adds to the figures.

General freezing technology

To capture the fresh food taste, color, smell and texture there is only one way – quick freezing. While Food Technologists considered one hour freezing as the fastest 20 years ago, we are today speaking of freezing time of minutes.

The only way to freeze fast is to cut the products into small or thin pieces. Big pieces cannot be frozen fast no matter how efficient and powerful cold is used. It is simply so that when frozen the ice form an insulation that hinder the quick freezing.

Freezing at the source – Block freezing for later IQF freezing destroys the product.

Freezers for the future – There are some brutal facts to take into consideration. In the tables below we will show you the particularities of all freezing equipment available today:

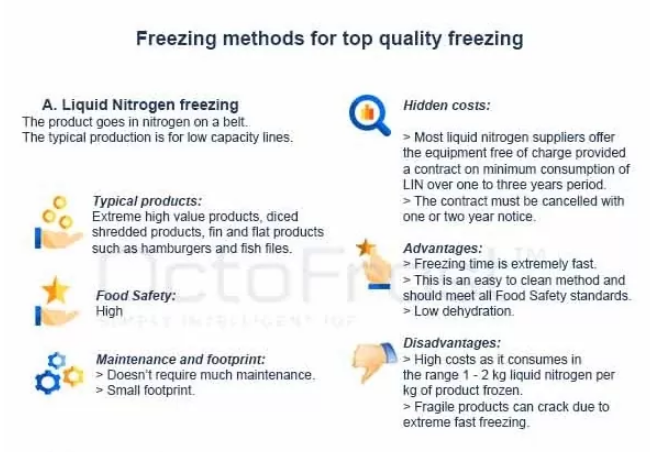

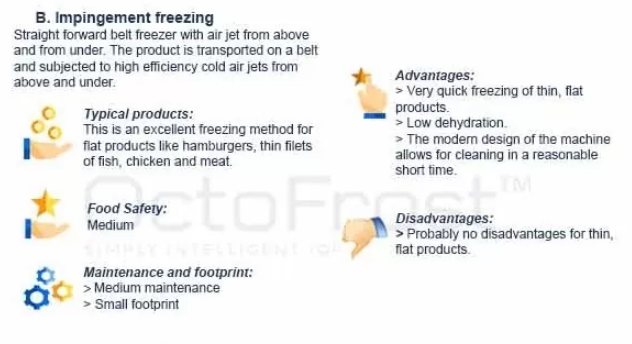

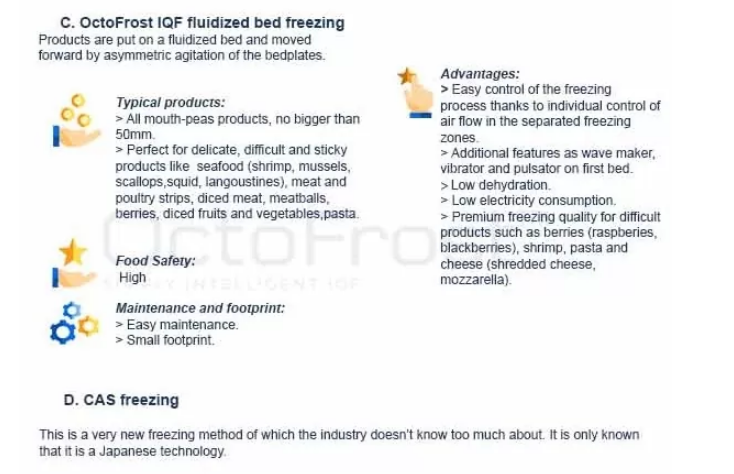

1. Freezing methods for top quality freezing

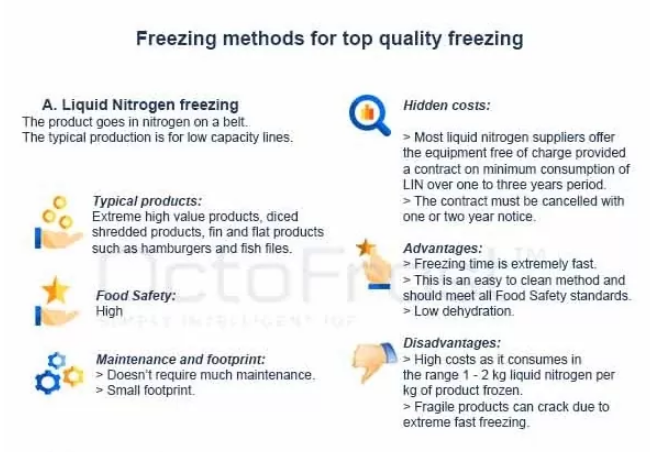

A. Liquid Nitrogen Freezing

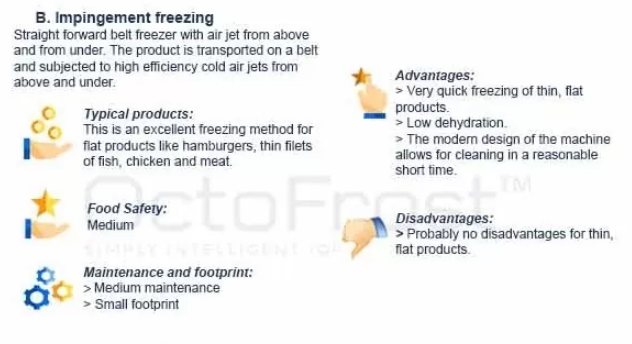

B. Impingement freezing

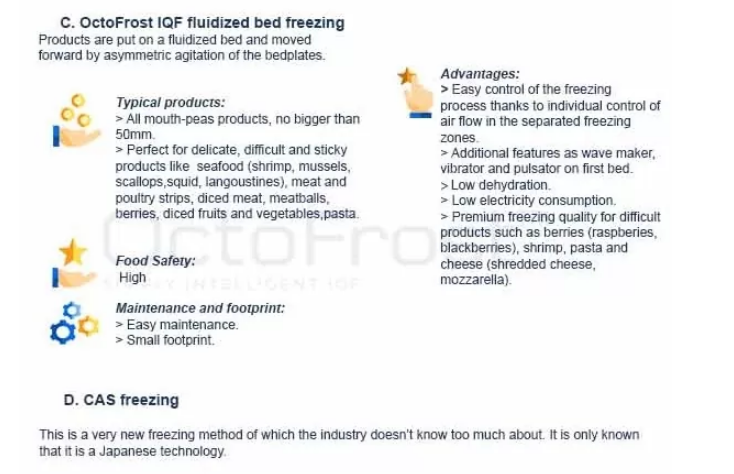

C. OctoFrost IQF fluidized bed freezing

D. CAS freezing

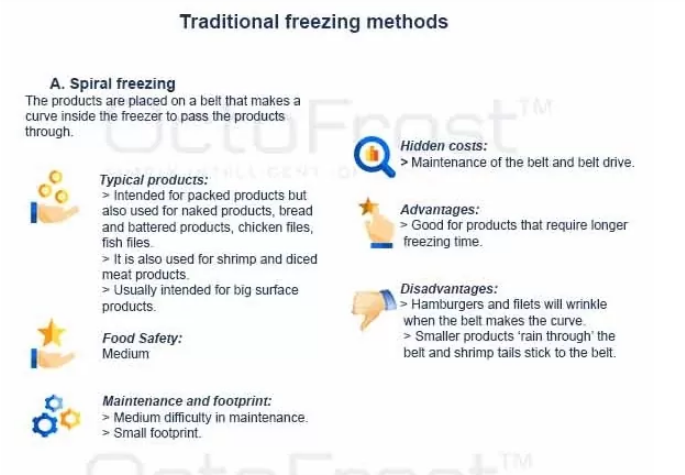

2. Traditional freezing methods

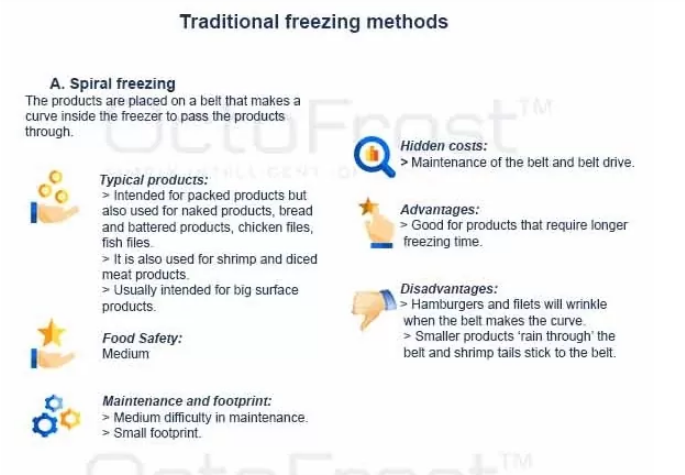

A. Spiral freezing

B. Traditional IQF belt freezing

C. Brine freezing

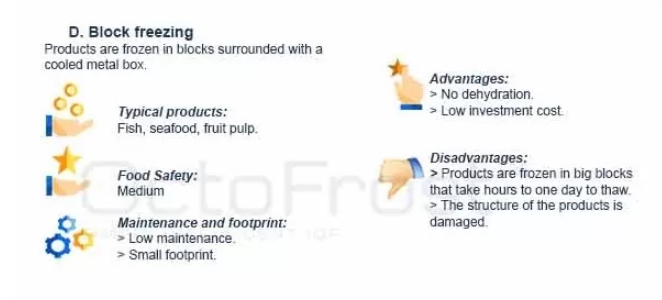

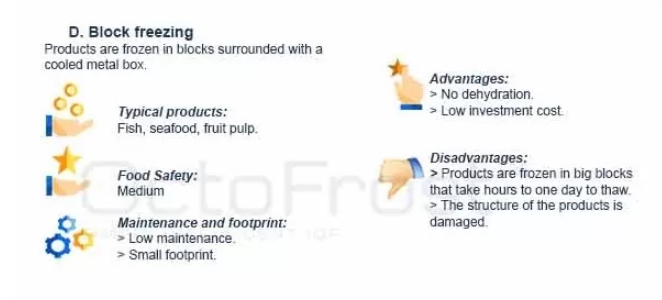

D. Block freezing

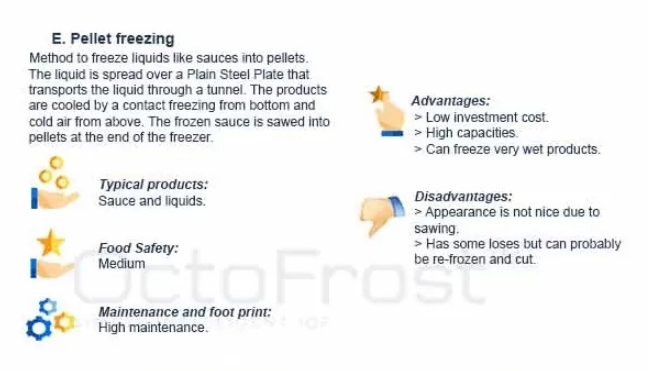

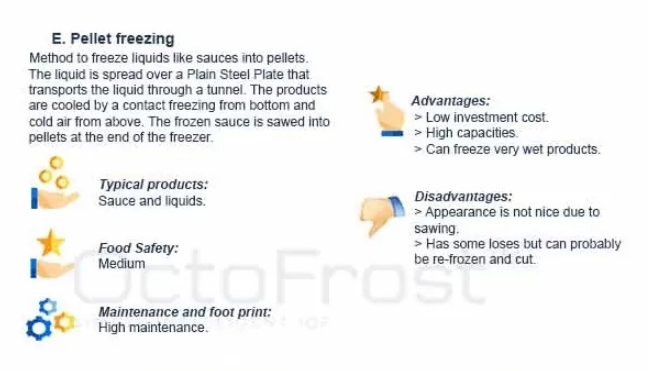

E. Pellet freezing

3. Different types of Cold Storage freezing

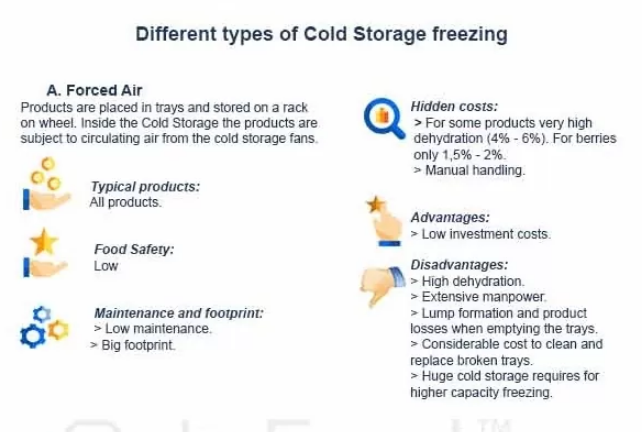

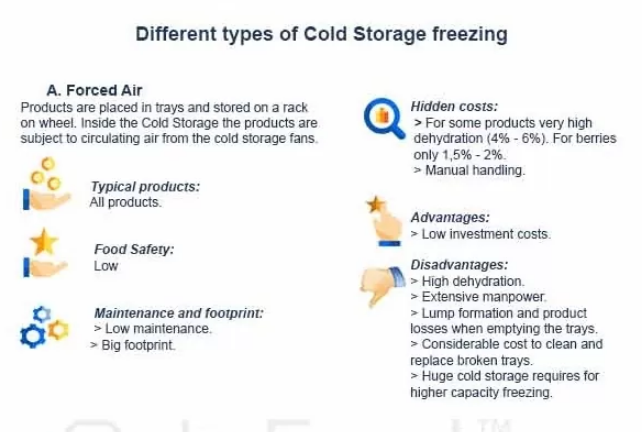

A. Forced Air

B. Push through tunnels

Source: OctoFrost™

Related Post

The true fishmeal carbon footprint

The established Life Cycle Analysis (LCA) methodology to assess the fishmeal carbon footprint only accounts for the vessel fuel and post-harvest processing energy while ignoring the carbon sequestration potential of fish.

View more

Freezing Tropical Fruits: Convenient and Effective Solution with Octofrost Machines

Tropical fruits are always a great choice for providing nutrition and fresh flavor to daily meals.

View more